Our Factory

Interested in partnering with Silk Grass Farms and learning more about our food-processing facility? Let’s talk!

About Our Factory

Silk Grass Farms built its 130,000-square-foot, state-of-the-art food processing facility in 2022, and added a 2-megawatt solar array soon after. This factory enables us to process foods from the Silk Grass family of farms as well as partner farms from across Belize, producing the freshest, highest-quality products possible.

Silk Grass Farms invested in this multimillion-dollar facility for a variety of reasons:

Commitment to product quality: We are dedicated to producing the highest-quality products. This dedication begins with our ecologically aligned sustainable farming practices, which yield juicier, healthier, more nutrient-dense foods. Thanks to the high-tech, world-class equipment in our factory, our production processes guarantee that fresh delicious flavor makes its way from our farm to your tastebuds.

Commitment to our workers: We aim to provide our employees, contractors, and visitors with a safe and healthy workplace, safeguarding the health and wellness of everyone impacted by our operations.

Commitment to Belize: Silk Grass Farms believes the natural abundance of Belize can be a driver of economic sustainability and prosperity for our nation. By partnering with and processing the crops of our fellow Belizean farmers, we hope to use our state-of-the-art processing facility to benefit not just Silk Grass Farms but the entire Belizean agricultural community.

Factory Capabilities

Our facility is equipped with several types of equipment capable of neutralizing microbes and food-borne pathogens, extending shelf life, and retaining the natural taste, texture, and nutrient value of our produce.

This equipment includes:

HPP (High-Pressure Processing): As the name implies, HPP applies up to 87,000 psi of pressure, to neutralize microbes and pathogens, extend shelf life, and retain the natural taste, texture, and nutrient value of a wide variety of pre-packaged foods without damaging proteins and enzymes.

Monoblock (tube-in-tube pasteurizer): The Monoblock pasteurizes with heat, homogenizes (if desired), and aseptically packs larger volumes of fruit purees and juices, plant-based milks and creams, in single strength or concentrate.

Retort: The Retort is used for high-heat sterilization of consumer-packaged goods (CPG) in glass jars, cans, or pouches.

IceGen: The IceGen converts liquids into a uniformly frozen slurry, preserving the taste, aroma, color and overall quality of the product for weeks in transit.

Microfiltration: The microfiltration process improves the quality, clarity, and taste of liquids such as our coconut water and cane juice.

Interested in learning more about the capabilities of our food-processing facility?

Safety + Sustainability

As stated in our Food Safety Policy, “Our primary objective is to manufacture and distribute products of the very highest standards. We will incorporate in [our] manufacturing process a high degree of food safety culture through GMP [Good Manufacturing Process] and Food Safety training and will ensure that all foods produced are fully complied with regulatory and international standards.”

Safe Quality Food (SQF) Certification: SQF demonstrates the highest level of food safety and quality control. Silk Grass Farms' factory received its SQF certification in 2023, and successfully recertified in 2024.

Health + Safety: Silk Grass Farms produces high-quality, ultra-safe food for positive social, economic, and environmental impact. All employees are responsible for producing safe products by building a culture of food safety and quality. Our goal is to keep improving our food safety management system to eliminate risks from supplier to customer. View our Health + Safety Policy.

Non–GMO + Kosher Pareve Certified: More than a dozen of our products and ingredients are certified by the Non-Genetically Modified Organism (GMO) Project—a reflection of our company's commitment to a transparent, natural, and non-GMO food system. We also received a stamp of approval from the EarthKosher Certification Agency, meeting yet another international quality standard.

Renewable Energy

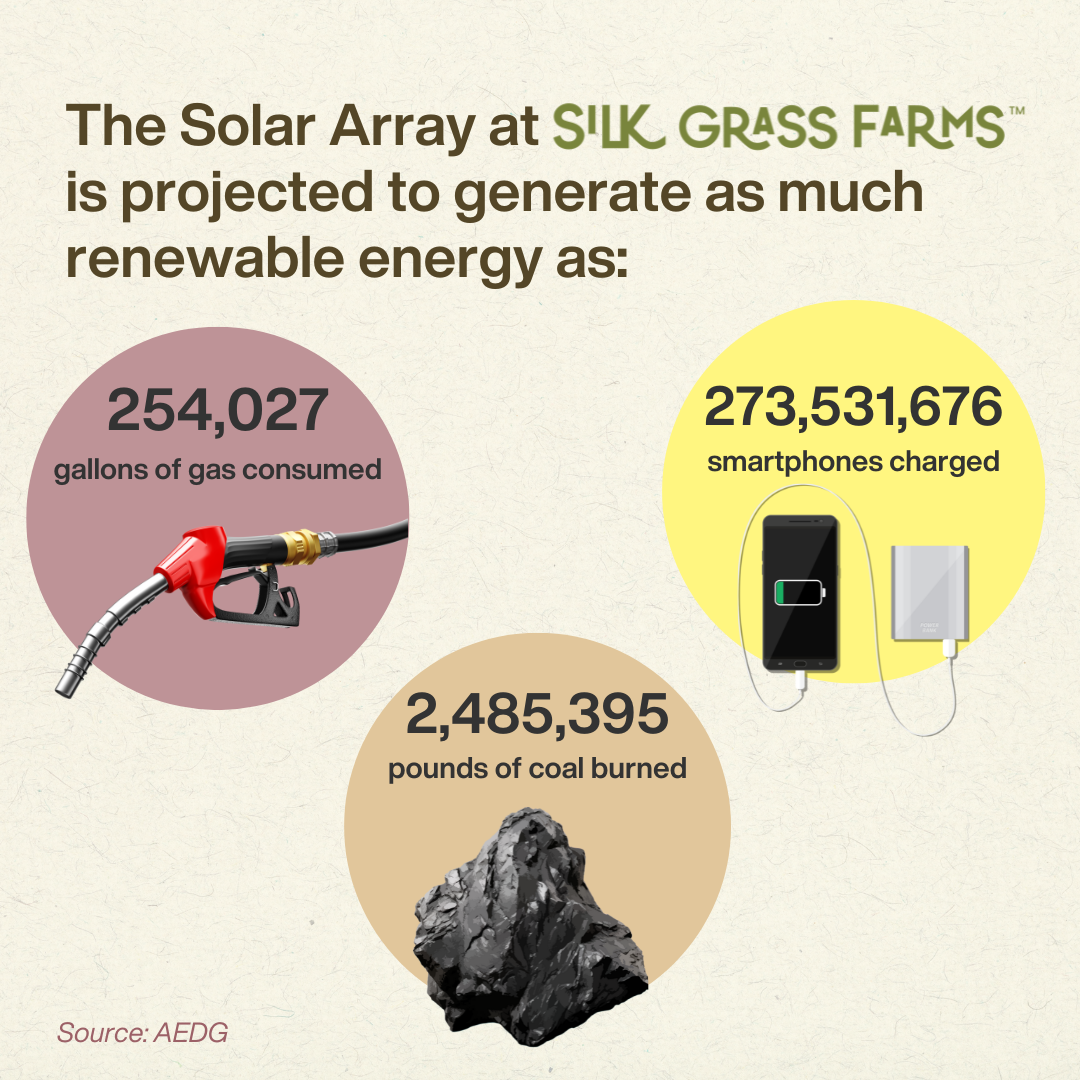

A 2-megawatt solar array harnesses the sun’s rays to operate the factory with sustainable energy, reducing our carbon footprint and our dependence on external power sources. The solar array is projected to generate 3,173 megawatt hours of clean, carbon-free energy and reduce carbon emissions by 2,249 metric tons each year.

Our solar powered factory is a crucial step in building a circular economy, following the regenerative agriculture practices that are restoring ecological health, and resulting in environmentally beneficial products whose entire profits support the Silk Grass Wildlife Preserve.

Food Categories

With our large-scale facility and broad scope of world-class equipment, Silk Grass Farms is uniquely positioned to process a vast array of fruits, vegetables, and rhizomes into high-quality, shelf-stable products. Each product must meet the “finished goods specification” outlined for that particular item. The process to produce these finished goods must be within the “guardrails” that SQF outlines.

The food categories we are equipped to process include (in alphabetical order):

Dragon Fruit

Ginger

Honey

Mango

Meats

Papaya

Passionfruit

Pineapple

Seafood

Soursop

Sugarcane

Vanilla

Watermelon

Yellow Ginger (Turmeric)